Unsere Experten haben ausschließlich bereits sehr gut bewertete Produkte getestet um den Wahrheitsgehalt der Rezensionen zu prüfen, sodass Sie das beste Produkt für Ihre Ansprüche bequem und einfach online bestellen können. Die tabellarische Bestenliste, stellt Ihnen Produkte mit ihren entscheidenden Merkmalen vor. Dabei wurden die 3D Drucker nach Bewertung und Expertenmeinung platziert. Den Testergebnissen folgt unsere Kaufberatung, wo wir Sie über weitere Vor- und Nachteile der verschiedenen 3D Drucker Optionen aufklären. Dort finden Sie auch alle wichtigen Informationen zu Funktionsweise, Anwendung und Eigenschaften der Produkte. So wollen wir und unser Technik-Experten Team Ihnen helfen, die für Sie beste Entscheidung zu treffen.![]() Das Technik-Expertenteam von k-wz.de hat für Sie einen fundierten 3D Drucker Test durchgeführt. Auf dieser Seite finden Sie neben dem Testbericht eine tabellarische Bestenliste, sowie unseren Kaufratgeber zu 3D Druckern verschiedener Hersteller.

Das Technik-Expertenteam von k-wz.de hat für Sie einen fundierten 3D Drucker Test durchgeführt. Auf dieser Seite finden Sie neben dem Testbericht eine tabellarische Bestenliste, sowie unseren Kaufratgeber zu 3D Druckern verschiedener Hersteller.

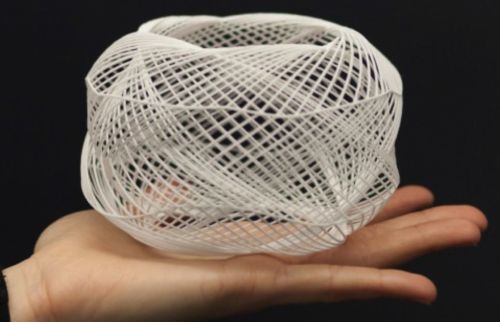

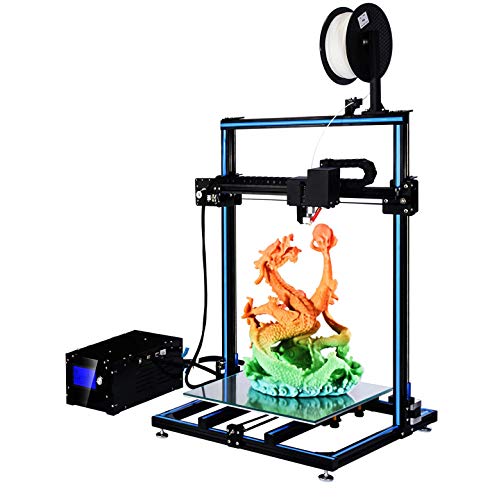

Der 3D-Druck hat die Industrie und inzwischen auch den Privatbereich erobert. Immer häufiger ist vom 3D-Drucker zu hören – besonders im medizinischen Bereich, wenn z. B. eine neue Niere oder Blase funktionsfähig »gedruckt« wurde. Aber was bedeutet das konkret? Nicht nur Informationen erreichen die Menschen immer schneller. Auch die Produktion von Stückzahlen erfolgt zunehmend computergestützt und in kürzerer Zeit. Was steckt aber hinter der Bezeichnung »3D-Drucker«? Wie unterscheiden sich die Geräte von herkömmlichen Druckgeräten? Das erfahren Interessierte hier – übersichtlich, umfassend, gleichzeitig kompakt und leicht verständlich. Bei einem 3D-Drucker handelt es sich um ein Gerät, das dreidimensionale Objekte erzeugen kann. Alle kennen den üblichen zweidimensionalen Druck auf Papier oder Karton. Die dreidimensionale Facette ist in den letzten Jahren hinzugekommen. Sie ermöglicht es, nicht nur die Breite und Länge, sondern ebenfalls die Höhe eines Objekts als wichtigen Faktor für den Druck zu berücksichtigen. Während früher vor allem industrielle Zwecke mit dem 3D-Druck verknüpft wurden, finden sich die Drucker heute ebenfalls in der Privatanwendung wieder. Jeder 3D-Drucker besteht im Grundsatz aus den folgenden Komponenten: Im Folgenden lesen sie Sie die Testergebnisse aus unserem 3D Drucker Test. Der Anycubic Mega-S 3D-Drucker wirbt mit guter Qualität, einem neuen Extruder, stabilem Vollmetall-Rahmen und einem Ultrabase Heizbett (ANYCUBIC S). Das Gerät bietet die gängige Kommunikation über SD-Karten und USB an. Es akzeptiert mehrere, gängige Eingabeformate bei der Software und setzt auf mehrere unterstützte Filamente. Die Bewegungsgeschwindigkeit ist mit 150 mm/s ein solides Maß für einen 3D-Drucker der günstigeren Preisklasse. Anfänger sowie fortgeschrittene Privatanwender können mit dem Anycubic Mega-S 3D-Drucker zu einem moderaten Preis von unter 400 Euro einige Ideen kreativ umsetzen. Technische Fakten zum Drucker Mega-S von Anycubic Der Hersteller Anycubic existiert seit 2015 auf dem Markt für 3D-Drucker. Seitdem hat sich das in China gegründete Unternehmen zu einen der Marktführer im Bereich 3D-Druck entwickelt. Inzwischen sind allein am chinesischen Standort Shenzhen rund 300 Mitarbeiter angestellt. Weitere Lagerstandorte befinden sich im deutschen Frankfurt, US-Bundesstaat Kalifornien sowie in Hongkong und natürlich in China. Anfangs begann das Unternehmen mit Zubehörteilen für bereits vorhandenen Druckern. Die Gründer folgten ihrem Herzen und waren bestrebt, die Technologie weiterzuentwickeln und vor allem zu verbessern. Das Ziel bestand darin, den 3D-Druck für alle zugänglich zu machen. Die Technologie sollte für jeden erschwinglich sein. Daraus entstand 2016 der erste Anycubic Mega, dem zügig weitere, sehr erfolgreiche Generationen von 3D-Druckern folgten. Vorteile Nachteile Für das Bastlerherz bietet der Hersteller Geeetech® einen 3D-Drucker-Baukasten an. Das Modell Acrylic Prusa I3 Pro B ist ein Do-it-yourself 3D-Drucker. Das Printer Kit nutzt als Technologie FFF und bietet eine bessere Schichtauflösung als andere Hersteller. Für Anfänger ist der Drucker-Bausatz gut geeignet, da er die beiden typischen Materialien – ABS und PLA – unterstützt. Der Drucker ist zudem ein relatives Leichtgewicht mit lediglich 8,5 Kilogramm. Gleichzeitig ist das 3D-Drucker Kit mit den gängigen PC-Betriebssystemen Windows, Linux und Mac kompatibel. Der Hersteller Geeetech® stammt aus Shenzhen, China. Das Unternehmen gründete sich 2011 mit dem Anspruch, den 3D Druck sowohl wirtschaftlich als auch einfach zu machen. Seit seiner Gründung ist »Shenzhen Getech Technology Co., Ltd« überaus erfolgreich und gilt als Pionier auf dem Gebiet des 3D-Drucks. Es vermarktet seine 3D-Drucker-Modelle weltweit auf sämtlichen Kontinenten. Dabei ist die Zielgruppe keineswegs auf den privaten Endverbraucher begrenzt. Die Kunden von Geeetech® stammen vielmehr aus sämtlichen Bereichen: Händler, Wissenschaftler, Studenten sowie Privatnutzer vertrauen der Marke Geeetech®. Vorteile Nachteile Das Modell Chiron von dem chinesischen Hersteller Anycubic bietet »Auto Levelling« und ein modulares Design an. Das sogenannte »Matrix Automatic Levelling« nutzt insgesamt 25 Messpunkte auf der Druckplattform. Damit ist eine praktische Kalibrierung in Echtzeit möglich. Daneben erlaubt das modulare Design den sofortigen Einsatz des 3D-Druckers. Anycubic nutzt bei diesem Modell außerdem das »Ultrabase Pro« Heizbett. Dadurch haften die Objekte besser auf dem Druckbett. Gleichzeitig geht damit eine leichte Ablösung des jeweiligen Teils einher. Außerdem ermöglicht der Chiron 3D-Drucker das problemlose Fortsetzen des Drucks im Fall eines Stromausfalls. Das verbessert letzten Endes die Druckqualität bei jenen Projekten, die mehr Zeit beanspruchen. Anycubic ist eine relativ junge Herstellermarke aus China. Sie begann ursprünglich als Unternehmen für Zubehör im 3D-Druck-Bereich, entwickelte sich ambitioniert rasch weiter, sodass 3D-Drucker die Unternehmensrichtung perfektionierten. Heutzutage ist Anycubic eines der führenden Unternehmen auf dem Markt der 3D-Drucker. Das Ziel der Firma besteht darin, den 3D-Druck für jeden erschwinglich werden zu lassen. Das zeigt sich in den relativ kostengünstig erhältlichen 3D-Printern des Herstellers. Vorteile Nachteile Der 3D-Drucker Ender 3 Pro gilt als erweiterte Variante von dem Druckermodell »Creality Ender 3«. Es enthält einen europäischen Standardstecker, der vor Spannungsspitzen schützen kann. Creality 3D ist ein Hersteller, der nicht nur Produkte vermarkten will, sondern auch Wissen weitergeben möchte. Daher handelt es sich beim 3D-Drucker Ender 3 Pro um ein DIY-Bausatz. Der 3D-Drucker ist bereits vormontiert, sodass die endgültige Zusammensetzung für den Endverbraucher besonders leicht gestaltet ist. Zugleich bietet das semi-fertige Kit die Gelegenheit, sich mit dem Design vertraut zu machen. Das Modell Ender 3 Pro unterstützt lediglich 1,75 mm starkes PLA als Filament. Das schränkt die Möglichkeiten der Nutzung zwar ein, bietet aber auch die Chance, als Einsteiger mit dem 3D-Drucker durchzustarten. Die maximale Bewegungsgeschwindigkeit von 180 mm/s ist ein gutes Mittelmaß zum Einstieg in die 3D-Drucktechnologie. Creality 3D ist ein spezialisierter Betrieb, der Endverbrauchern eine erschwingliche Lösung für 3D-Druck bieten möchte. Dabei bezeichnet sich das Unternehmen selbst als branchenführend. Auch diese Marke ist – ebenso wie Anycubic und Geeetech® – im chinesischen Shenzhen beheimatet. 2014 wurde Creality 3D gegründet. Innerhalb kürzester Zeit avancierte das Hightech-Unternehmen von einem 4-Mann-Betrieb zu einem Konzern mit über 550 Mitarbeitern. Beinahe rund um den Globus ist Creality 3D mit Standorten vertreten. Auf dem asiatischen Kontinent hat das Unternehmen insgesamt vier Standorte, während sich auch in Belgien und ganz Europa Niederlassungen befinden. Weitere befinden sich seither im Aufbau. Im Bereich der 3D-Drucktechnologie entwickelte sich Creality 3D beständig weiter. Den Anfang des Erfolgs bildete der 3D Drucker CR-3, ehe zügig weitere Modelle folgten. Inzwischen hat Creality 3D über 20 verschiedene 3D-Drucker herausgebracht. Dazu zählen sowohl DIY Kits als auch sofort einsatzfähige Komplettmodelle. Das Unternehmen hat sich die Punkte Integrität, Innovation, Verantwortung und Win-Win als Firmenphilosophie auf die Fahnen geschrieben. Vorteile Nachteile Der Bibo 2 3D-Drucker überzeugt mit einer Vielzahl an Funktionalität. Der Drucker ist mit einem Gravurmodul ausgestattet, sodass das Gravieren von Objekten ebenfalls möglich ist. Die Kommunikation mit dem Gerät erfolgt unkompliziert mittels USB-Anschluss, SD-Karten-Schnittstelle, WI-FI und dem integrierten Vollfarb-Touchscreen. Der stabile Rahmen ist mit einer 6 mm dicken Aluminiumverbundplatte ausgestattet. Das macht den Bibo 2 besonders robust für den Einsatz mit den gängigen Filamenten ABS, HIPS (auflösbares Filament), TPU (flexibles Filament) und PLA. Dabei erkennt der 3D-Drucker vollkommen automatisch, welches Filament für den Druck genutzt wird. Der integrierte Dual Extruder ermöglicht es außerdem, zwei Farben zu drucken. Das bietet vielseitige Gestaltungsmöglichkeiten für 3D-Objekte aus dem Drucker. Objekte lassen sich zudem kopieren, sodass der 3D-Drucker zwei Werkstücke gleichzeitig druckt. Durch diese Funktion lässt sich die Druckzeit mindestens halbieren. Zusätzlich ist es mit dem Bibo 2 3D-Drucker mit dem Gravurmodul möglich, dünne Materialien wie Papier, Karton oder dünnen Kunststoff zu schneiden. Daneben ist das Druckbett sowohl beheizbar als auch abnehmbar. Der Hersteller »Shaoxing Bibo Automatic Equipment Co., Ltd.« ist einer der erfolgreichsten Hersteller für 3D-Drucker. Insbesondere in China ist das Unternehmen erfolggekrönt. Der Sitz von Bibo ist im chinesischen Shaoxing. Dort wurde es von Universitätsabsolventen gegründet und hat inzwischen Produktionsstandorte in den USA, Kanada, Russland, China und Großbritannien. Das Unternehmen gewann außerdem den ersten Preis in einem Design-Wettbewerb der angesehenen Zhejiang Universität. Zugleich erhielt das Unternehmen Bibo den ersten Preis in einem national stattfindenden Wettbewerb für Innovation. Vorteile Nachteile Inhaltsverzeichnis Jeder 3D-Drucker arbeitet ähnlich: Der Nutzer steuert über die Bedieneinheit (z. B. ein Touchscreen) die Einstellungen. Der Extruder verarbeitet anschließend das Material (d. h. Filament) und spritzt es über die Düse auf die Druckplatte. Die Details hinter der Funktionsweise beleuchten die folgenden Abschnitte ausführlich. Der Drucker benötigt zusätzlich passendes Material. Beim 3D-Druck sind das häufig entweder die sogenannten Filamente oder Harz. Als gängiges Material für den Druck kommen hauptsächlich Kunststoffe oder Metalle zum Einsatz. Aber auch Sand ist als Ausgangsmaterial möglich. Bevor der Drucker überhaupt starten kann, ist eine entsprechende Vorlage vonnöten. Der 3D-Drucker muss schließlich wissen, welche Form, Farbe und Abmessung das Objekt erhalten soll. Zu diesem Zweck ist eine entsprechende Software notwendig. CAD-Dateien liefern die entsprechende Vorlage, damit der Drucker drucken kann. Allerdings ist nicht immer die eigene Kreativität gefragt. Inzwischen existieren 3D-Druckstudios. Solche Studios haben sich auf die Erstellung von Modellen professionalisiert. Auf diese Weise könne Laien beispielsweise eine 3D-Miniatur von sich selbst oder anderen Personen erstellen lassen. Es erfordert dafür in jedem Fall Fotografien von allen Seiten des Modells. Als weitere Option steht das Internet zur Verfügung. Einige Webseiten bieten vorgefertigte Modelle an. Diese können Nutzer kaufen und herunterladen, um sie zu nutzen. Wer einen 3D-Drucker nutzen will, benötigt das passende Filament dazu. Obwohl 3D-Drucker enorm vielseitig nutzbar sind, gibt es dennoch Einschränkungen in der Umsetzung. Grundsätzlich sind Filamente vergleichbar mit Tinte im herkömmlichen Drucker. Ein Tintenstrahldrucker weist daher eine gewisse Ähnlichkeit mit 3D-Druckern auf. Für den 3D-Druck kommen vor allem thermoplastische Kunststoffe zum Einsatz. Sie sind durch Hitze formbar, was sie zu einem optimalen Ausgangsmaterial für den 3D-Print macht. Normalerweise verwenden Nutzer ABS, PLA oder andere Kunststoffe, um dreidimensionale Objekte zu drucken. Ein PLA-Filament ist für den Privatgebrauch gut nutzbar. Hinter der Abkürzung verbirgt sich der Kunststoff Polyactide. Dieser ist auch als Polymilchsäure geläufig. Es handelt sich genau genommen um eine Art Polyester. Dieser Kunststoff zeichnet sich dadurch aus, dass er sich bei Wärme (ungefähr ab 60 Grad Celsius) verformen lässt. Für den 3D-Druck ist diese Eigenschaft optimal. Zusätzlich schrumpft das Material weniger beim Abkühlen. Allerdings ist es ratsam, die fertigen Objekte nicht bei hohen Außentemperaturen im Auto zu lassen (z. B. Hochsommer). Im Handel ist das PLA-Filament als Spule erhältlich. Die Stärken des Feinmaterials unterscheiden sich voneinander. So sind Stärken von unter 100 mm ebenso erhältlich wie solche über 200 mm. Das Material ABS unterscheidet sich grundlegend von PLA. Die Abkürzung steht für Acrylnitril-Butadien-Styrol. Dabei handelt es sich um einen Kunststoff, der Temperaturen über 100 Grad Celsius benötigt, um formbar zu sein. Die hohen Temperaturen führen dazu, dass ABS beim Abkühlen schrumpft. Das macht das Thermoplast schwer verarbeitbar. Um das Schrumpfen während des Druckes zu verhindern, muss die Arbeitsfläche beheizt sein. Für den Privatgebrauch – speziell als Anfänger – ist ABS deshalb weniger gut geeignet. Die Filamente entsprechen im Prinzip der Tinte beim Tintenstrahldrucker. Ein 3D-Drucker nutzt sie, um das Werkstück anzufertigen. Dabei ist das Filament jedoch längst nicht das wichtigste Teil beim 3D-Druck. Der sogenannte Extruder ist ebenfalls bedeutsam. Er ist verantwortlich für die Hitze, um die Filamente zu schmelzen. Zusätzlich übernimmt der Extruder das Aufspritzen des flüssigen Materials auf die Arbeitsfläche. Dazu bewegt er sich mithilfe von Zahnriemen auf Schienen. Der Extruder ähnelt somit der Druckerpatrone beim Tintenstrahldrucker. Bei ihnen kommt es darauf an, das Filament gleichmäßig aufzutragen. Der Extruder trägt das Material schichtweise auf die Druckplatte auf. Dabei ist die Feinheit ein wichtiger Faktor beim 3D-Druck. Erfolgt der Druck mit dem Extruder nicht fein genug, sind die Schichten beim fertigen Objekt erkennbar. Nicht immer ist dies auch erwünscht. Deshalb lohnen sich 3D-Drucker für viele, wenn sie eine Schichtfeinheit von bis zu 20 Micron erlauben. Wichtig: Dieser Aspekt beeinflusst den Preis für den 3D-Drucker. Der Extruder trägt das Filament im Idealfall in einer Weise auf, bei der das Material weder verläuft, noch Löcher ausbildet. Durch die hohe Geschwindigkeit und Temperatur mit der der Extruder arbeitet, ist zwar eine Vielzahl an Objekten möglich. Aber alles steht und fällt mit dem richtigen Filament. Stimmt beim Material die Qualität nicht, droht ein Druckstau. Das kann das gesamte Druckprojekt beeinträchtigen. Es existieren im Handel Single-Extruder und Mehrfach-Extruder (Dual- oder Trio-Extruder). Für gewöhnlich nutzen private Anwender die Single-Variante. Wer zur gleichen Zeit mehrere Farben drucken will und dementsprechend mehrere Filamente verarbeiten möchte, leistet sich eher Mehrfach-Extruder. Diese Geräte sind jedoch deutlich teurer als jene mit Single-Extruder. Daher eignen sie sich selten für den Heimgebrauch. Der Druckvorgang selbst ist komplett computergestützt. Anhand der Vorgabe trägt der Drucker die Filamente in den vorgegebenen Farben, Formen und Abmessungen schichtweise auf. Stück für Stück entsteht auf diese Weise ein 3D-Objekt. Das Drucken dreidimensionaler Werkstücke ist mit unterschiedlichen Fertigungsverfahren möglich. Eines ist das sogenannte »additive Fertigungsverfahren«. Es ist im Groben vergleichbar mit einem Backvorgang. Denn die Materialien werden zunächst geschmolzen, bevor der Drucker alles zu einer Einheit »backt«. Speziell beim additiven Vorgehen arbeitet der 3D-Drucker mit den Technologien Direct Metal Printing (DMP), Lasersintern (SLS) sowie Stereolithografie (SLA). Ein weiteres Verfahren ist das sogenannte FDM- oder Schmelzdruck-Verfahren. FDM ist die Abkürzung für »Fused Deposition Modeling«. Dieses Verfahren ist vor allem für den Privatanwender interessant, da viele 3D-Drucker für den Heimgebrauch dieses Verfahren nutzen. Dabei kommt ein Laserstrahl zum Einsatz. Der 3D-Drucker verflüssigt das verwendete Filament zunächst. Dies geht mit einer hohen Temperatur durch den Extruder einher. Das flüssige Material kann danach durch den Extruder auf die Arbeitsfläche gespritzt werden. Der Laserstrahl des 3D-Druckers dient letztlich dazu, das Werkstück aushärten zu lassen. Für den 3D-Druck heißt das: die Arbeitsfläche immer weiter abzusenken. Dadurch ist es möglich, dass der Laserstrahl stets auf derselben Höhe aktiv ist. Bei der Nutzung eines 3D-Druckers haben insbesondere private Anwender die Wahl zwischen den gängigen Verfahren FDM und SLA. Doch welches überzeugt mehr? Wann ist das eine Verfahren empfehlenswerter als das andere? Dazu sind die Techniken genauer zu betrachten. Das FDM-Verfahren basiert auf ein Filament, das wie ein Draht auf eine Spule gewickelt ist. Das Ende des Filamentfadens gehört in den Extruder, der es schmilzt und weiterverarbeitet. Diese Methode nutzt besonders häufig flexible Kunststoffe. Das SLA-Verfahren basiert im Gegensatz zum FDM-Verfahren nicht auf Filamente, sondern auf flüssiges Harz. Die 3D-Drucker sind deshalb auch anders ausgerichtet: Die Druckplatte befindet sich kopfüber, das Harz befindet sich häufig in einer Wanne. Beim Druck taucht die Platte in das Harz ein. Anschließend kommt ein Laser zum Einsatz, der das Harz aushärten lässt, da es UV-sensitiv ist. Auf diese Weise entsteht das zu druckende Objekt. Beide Methoden haben ihre Vorzüge. Im Endeffekt zählt das, was der Nutzer erwartet. Fakt ist aber, dass beim SLA-Verfahren keine deutlich sichtbaren Schichten entstehen. Durch das gleichmäßige Eintauchen und Aushärten erhält der Anwender ein ebenmäßigeres Werkstück. Gleichzeitig besteht der Haken der ganzen Sache darin, dass das Harz deutlich teurer ist als die Filamente beim FDM-Druck. Zudem ist der Reinigungsaufwand höher, sobald weitere Farben ins Spiel kommen. Denn die sogenannte Resin-Wanne ist bei einem Farbwechsel jedes Mal zu säubern. Aufgrund der UV-Sensitivität vom Harz ist außerdem zu bedenken, dass beim SLA-Verfahren das Resin (d. h. das Harz) nicht dem Tageslicht ausgesetzt wird. Sind 3D-Drucker lediglich technischer Schnickschnack oder sind die Geräte tatsächlich nützlich? Wofür werden sie heute eingesetzt? In erster Linie erfreuen sich kreative Personen an der Technologie. Aber längst ist bekannt, wie vielseitig 3D-Drucker tatsächlich nutzbar sind. Sowohl in der Industrie als auch im privaten Sektor finden die Geräte immer mehr Einsatzbereiche. Früher dienten 3D-Drucker hauptsächlich der Herstellung von Modellen oder Prototypen – Einzelstücken also. Das hat sich mit der Weiterentwicklung der Technik zunehmend gewandelt. Der 3D-Druck ist inzwischen in der Medizin ebenso heimisch geworden wie bei der Herstellung von Schmuck, der Luftfahrttechnik, Raumfahrttechnik sowie Dentaltechnik. Kennzeichnend ist, dass sich Objekte in kleiner Größe, aber in hoher Anzahl herstellen lassen. Damit sind 3D-Drucker grundsätzlich geeignet, um in Konkurrenz mit z. B. klassischen Spritzgussverfahren zu treten. Heute nutzen Anwender die Drucker immer noch für Prototypen und Einzelanfertigungen. Das gilt besonders in den Bereichen der Architektur, des Modellbaus, der wissenschaftlichen Arbeit im Labor sowie im Maschinenbau. Die Verpackungsindustrie profitiert hingegen von der Fähigkeit der 3D-Drucker zur Serienfertigung. Speziell die Medizintechnik ist ein schnell voranschreitendes Forschungsgebiet im 3D-Biodruck. Obwohl 3D-Drucker wachsende Einsatzgebiete für sich erobern, ist ihre Anwendung dennoch eingeschränkt in der Industrie. Die Drucker werden vor allem für die metallverarbeitenden Zweige interessant. Allerdings ist ihr Einsatz kostspieliger als herkömmliche Verfahren. Zudem ist die Qualität und Druckdauer vieler 3D-Drucker noch verbesserungswürdig. Dadurch nutzen längst nicht alle Industrieunternehmen diese Technologie. Gleichzeitig ist der Wissensstand der Unternehmen oft nicht umfassend genug, um die 3D-Drucktechnologie flächendeckend einzusetzen. Anders ist es für Privatnutzer. In diesem Bereich lassen sich viele Alltagsobjekte, Dekorationsstücke oder auch Schmuck in geringer Stückzahl herstellen. Die Möglichkeiten sind eine Frage der Kreativität. Stiftebecher, Modellbauten oder Spielzeugfiguren sind die gängigsten Objekte, die mit dem heimischen 3D-Drucker angefertigt werden. Der 3D-Print ist nicht nur im wissenschaftlich-medizinischen, also biologischen, Sektor vorangeschritten. Auch in den Bereichen Physik und Chemie kommen 3D-Drucker gehäuft zum Einsatz. In diesen naturwissenschaftlichen Teilbereichen nutzen Laboratorien die 3D-Drucker hauptsächlich, um Messapparaturen und Gefäße für Reaktionen zu erzeugen. Insbesondere in der Chemie kommen die Drucker für Minireaktoren zur Anwendung. Abseits der Wissenschaft finden sich die Drucker ebenfalls im künstlerischen Bereich wieder. Die Kunst profitiert speziell im Bereich der Bildhauerei vom dreidimensionalen Druck. Für jegliche Skulptur lässt sich das gewünschte Objekt digital vorausplanen, ehe der 3D-Drucker einen großen Teil der Fertigungsarbeit übernimmt. Künstler müssen in diesem Fall lediglich die Vorarbeit am Computer und die Nachbearbeitung des Kunstobjekts übernehmen. Somit vereinfachen 3D-Drucker die Arbeit des modernen Künstlers. Nicht zuletzt eignen sich 3D-Drucker sehr gut, um Modelle von Gebäuden anzufertigen. Auch das Bauwesen nutzt zunehmend den dreidimensionalen Druck. Dabei sind die 3D-Drucker vorwiegend als sogenannte Portalroboter gefragt. Sie sind in der Lage, die im Computer festgehaltenen Steuerungsdaten zu interpretieren und den Beton präzise in den jeweiligen Rahmen einzuspritzen. Für den Rohbau eines Gebäudes ist diese Anwendung von 3D-Druckern ideal, da es vor allem Arbeitskraft spart. Das ermöglicht die Fertigung kompletter Häuser ganz nach einer Vorlage am Computer. Zudem lässt sich das Material in exakt passenden Mengen nutzen. Fehler bei der Ausführung sind durch die Nutzung von einem 3D-Printer weniger wahrscheinlich. Bei all den Überlegungen stellt sich die Frage, welche Arten von 3D-Drucker erhältlich sind. Worin unterscheiden sie sich? Prinzipiell sind 3D-Printer für Privatanwender in verschiedenen Ausführungen erhältlich. Auf dem Markt sind dementsprechend Drucker verfügbar, die bereits fertig sind und demnach direkt einsatzfähig sind. Daneben gibt es 3D-Drucker-Kits und sogenannte DIY-Lösungen. Dabei sind die einzelnen Bausätze (das Kit) erst zusammenzubauen, ehe der Drucker nutzbar ist. Gleichzeitig stellt sich die Frage: Was muss ein 3D-Drucker können? Welche Ansprüche sind zu erfüllen? Gerade im privaten Bereich sind fertig konzipierte 3D-Drucker beliebt. Insbesondere die erste Inbetriebnahme ist häufig einfach gestaltet. Neulinge beim 3D-Print finden eine breite Palette unterschiedlicher Marken und Hersteller. Bei diesen Druckertypen fällt vor allem die leichte Bedienbarkeit auf. Sie ermöglichen häufig die Verbindung mit dem Computer, Smartphone, SD-Karten oder USB-Sticks. Diese Fertiglösungen benötigen von allen 3D-Druckern am wenigsten technisches Vorwissen. Daher sind sie ideal für Einsteiger in die Materie. Fortgeschrittene Nutzer des 3D-Drucks suchen mitunter gerne die kreative Herausforderung. Ein Bausatz oder ein 3D-Drucker-Kit ist optimal, um sich kreativ auszutoben. Dabei erhalten Käufer keinen fertig zusammengesetzten 3D-Drucker. Stattdessen sind lediglich die einzelnen Bestandteile enthalten, die der Anwender dann selbst zusammenbaut oder endmontiert. Selbstverständlich sind entsprechende Bauanleitungen verfügbar, die beim Zusammenbau behilflich sind. Gleichzeitig gestaltet sich der Zusammenbau im Regelfall weitaus weniger kompliziert als zu vermuten wäre. Im Zweifelsfall können Internetseiten (z. B. Anleitungen auf der Videoplattform Youtube) weiterhelfen. Neben der Nutzung im privaten Bereich kommt jene im industriellen oder wirtschaftlichen Sektor infrage. Für jene professionell anmutenden Ansprüche eignen sich multiple 3D-Drucker gut. Sie sind auch für den ambitionierten Heimanwender geeignet. Allerdings lohnen sie sich ausschließlich, wenn viele Druckoptionen und kreative Möglichkeiten gewünscht sind. Für zuhause lohnen sie sich kaum. Sie sind nicht nur sehr kostspielig in der Anschaffung und im Gebrauch, sofern sämtliche Facetten ausgereizt werden sollen. Normalerweise finden sich solche hochwertigen 3D-Drucker im Bereich der Forschung und Entwicklung wieder. Neben der alltagstauglichen Umsetzbarkeit von schöpferischen Ideen lassen sich mit einem einzelnen Drucker viele verschiedene Teile fertigen. Dadurch verfügen die Geräte über einen großen Vorzug gegenüber dem klassischen Spritzgussverfahren. Das führt dazu, dass 3D-Drucker für Betriebe ungemein wertvoll sein können. Insbesondere im Bereich der Produktfertigung. Das alles geht zwar mit den Anschaffungskosten einher, jedoch lassen sich Kosten bei der tatsächlichen Herstellung verschiedenster Objekte sparen. Zuletzt können 3D-Drucker in etlichen Fällen energetisch günstiger sein als andere Herstellungsmethoden (z. B. Spritzgussverfahren). Vorteile zusammengefasst: Obwohl heutzutage schon vieles möglich ist und sich die 3D-Drucker in wachsender Anzahl auf dem Markt finden lassen, gibt es dennoch einige Schwächen. Das beginnt bei den Kosten für die Anschaffung. Speziell für den Heimanwender sind die günstigen Drucker nicht immer optimal. Wer auf Qualität beim 3D-Druck setzt, muss im höheren dreistelligen, eher vierstelligen Bereich investieren. Das zeigt gleichzeitig einen weiteren Nachteil: Gerade die günstigen Modelle (ab 150 Euro) bieten nicht immer die Qualität, die wünschenswert wäre. Gleichzeitig kann ein Mangel an technischem Verständnis schnell frustrierend werden. Denn der Umgang mit dreidimensionalen Vorlagen erfordert ein anderes Verständnis als es beim Drucken auf Papier der Fall ist. Wer nicht im Vorfeld weiß, welche Objekte der Drucker drucken soll, fühlt sich mitunter verleitet ein kostengünstiges Gerät zu kaufen. Diese erlauben aber nicht alle Möglichkeiten des 3D-Drucks. Gleichzeitig sind die Kosten mit der Nutzungshäufigkeit abzuwägen. Oft lohnen sich die 3D-Drucker erst, wenn sie regelmäßig gebraucht werden. Nachteile zusammengefasst: Wer kann einen dreidimensionalen Druck überhaupt im Alltag nutzen? Für wen produzieren die Hersteller von 3D-Druckern die Geräte? Der Markt bietet eine immer größer werdende Auswahl an Druckern. Dabei wird hauptsächlich zwischen drei Nutzergruppen unterschieden: Es erscheint sinnig, dass die Drucker für den industriellen Gebrauch besonders hochwertig und leistungsstark sind. Auch der Preis bezeugt diese Tatsache. Denn industrielle 3D-Drucker sind absolute Profi-Geräte und kosten leicht eine Summe im sechsstelligen Bereich (100.000 Euro und mehr). Diese Drucker sind ideal, um hochpräzise komplexe Objekte oder hohe Stückzahlen anzufertigen. Die Drucker sind für wissenschaftliche Forschungen optimal. Speziell der 3D-Biodruck macht große Fortschritte – Organe aus dem 3D-Drucker scheinen nicht allzu ferne Zukunft zu sein. Medizinische Unternehmen, die Chemieindustrie, Metallbauer, Autobauer, Architekten und viele andere Firmen, die mit Produktion verknüpft sind, können von 3D-Druckern profitieren. Gilt das auch für den 3D-Drucker im Privathaushalt? Die Ansprüche sind im heimischen Gebrauch für gewöhnlich weniger stark ausgeprägt als in der Industrie oder Wirtschaft. Da die Geräte für Privatanwender bereits relativ günstig erhältlich sind, macht der Durchschnittsverbraucher vor allem qualitativ Abstriche. Die Geräte sind zwar inzwischen massentauglich und günstig erhältlich. Dennoch sollte jeder sich fragen, ob sich die Anschaffung für den eigenen Gebrauch wirklich lohnt. Ist es die Absicht, regelmäßig dreidimensionale Objekte zu drucken, kann sich die Investition durchaus als lohnend herausstellen. Der 3D-Drucker lohnt sich im heimischen Umfeld vor allem für Bastler, Tüftler und Kreative oder Technikbegeisterte. Es lassen sich Gegenstände für den Modellbau herstellen ebenso wie Vasen oder Hüllen für das Smartphone. Allerdings ist es für Kreativgeister angebracht, genau abzuwägen. Denn wer lediglich ab und zu ein Objekt zu drucken gedenkt, kann sein Geld häufig besser anlegen als in einen kostspieligen 3D-Drucker. Inzwischen bieten immer mehr Shops den 3D-Print an, sodass sich dieser Weg für den eher seltenen Druck oft mehr lohnt. Beim 3D-Drucker fragt sich manch einer: Gibt es eine Alternative zu der Technologie? Welche Methoden sind ebenfalls realisierbar und alltagstauglich? Zahllose Industrieunternehmen beweisen, dass das herkömmliche Spritzgussverfahren geeignet ist, um Formen, Modelle, Prototypen und ganze Produkte herzustellen. Das Verfahren durch Spritzguss ist aufwendiger als beim 3D-Drucker. Denn die Spritzgussformen sind nicht »mal eben« für andere Farben oder Formen nutzbar. Vielmehr sind Anpassungen und aufwendige Reinigungsprozesse notwendig, um das Spritzgussverfahren alternativ zum 3D-Druck zu nutzen. Zudem sind Spritzgussverfahren lediglich für professionell agierende Unternehmen praktikabel. Für den persönlichen Gebrauch, bei dem kleine Modellstücke oder Einzelanfertigungen in kleiner Größe gefragt sind, eignet sich dieses Alternativverfahren nicht. Für den Privatgebrauch existiert dennoch eine Alternative zum 3D-Drucker: Die sogenannte FormBox. Dieses Tischgerät funktioniert ähnlich wie das größer dimensionierte Spritzgussverfahren. Bei der Formbox entsteht eine Gussform mithilfe von einer formbaren Kunststofffolie. Die Technik dahinter funktioniert mit einem Vakuum: Das Vakuum presst das gewünschte Objekt in die Kunststofffolie, sodass diese als fertige Gussform genutzt werden kann. Wie kommt das Vakuum zustande? Jeder, der sich mit dem technischen Verständnis für 3D-Drucker schwertut, wird erleichtert aufatmen. Denn für die Formbox ist lediglich ein Staubsauger nötig, der das nötige Vakuum bewirkt. Diese Form lässt sich dann mit dem gewünschten Material (z. B. Zement, Kuvertüre, etc.) füllen. Das Material härtet aus – fertig ist das 3D-Objekt! Abgesehen von der direkten Alternative zum 3D-Drucker sind lediglich alternative Filamente erhältlich. Beispielsweise kommen Kaffeesatz, Hanf, Holz oder Sandstein als Filamentalternative infrage. In jedem Fall eignen sich die natürlichen Substanzen aber nur in Kombination mit einem herkömmlichen 3D-Drucker-Filament als Material zum plastischen Drucken. Wer sich einen 3D-Drucker zulegen will, sieht sich vor allem mit technischen Feinheiten konfrontiert. Besonders im Bereich des 3D-Drucks ist die Palette an möglichen Geräten breit gefächert. Für Einsteiger im 3D-Print kann die Auswahl regelrecht überwältigend sein – besonders im Internet. Worauf ist also zu achten, wenn ein 3D-Drucker zu kaufen ist? Das offensichtlichste Merkmal ist der Preis vom 3D-Drucker. Viele Privatanwender wollen möglichst günstig einkaufen und achten auf den Preis. Die modernen 3D-Drucker für Anfänger und Einsteiger sind bereits für rund 500 Euro erhältlich. Allerdings sollte der Preisfaktor kein alleiniges Kriterium sein. Gerade 3D-Drucker benötigen technisches Verständnis, um das passende Modell für die eigenen Zwecke auszuwählen. Als Daumenregel gilt daher: Je höher der Anspruch beim dreidimensionalen Druck ist, desto tiefer ist bei der Anschaffung in die Tasche zu greifen. Was heißt das konkret und in Zahlen ausgedrückt? Drucker für den privaten Gebrauch sind für weniger als 1000 Euro erhältlich. Die günstigsten 3D-Printer kosten üblicherweise rund 300 Euro. Bausätze bzw. 3D-Drucker-Kits sind sogar zum Preisen zwischen 100 und 200 Euro verfügbar. Ein gutes Mittelklasse-Modell kostet im Regelfall aber um die 500 Euro und bietet qualitativ alle Grundlagen, die für den Druck von 3D-Objekten zum Privatnutzen vonnöten sind. Soll der Drucker allerdings mehr Farben, Formen, Materialien oder kompliziertere Modelle drucken können, kostet er entsprechend mehr. Geschlossene Modelle mit einem Doppel-Extruder sind beispielsweise für etwa 4000 bis 6000 Euro erhältlich. Für die Industrie sind die Preise je nach Anwendungsgebiet nochmals deutlich höher. Industrielle 3D-Drucker kosten üblicherweise zwischen 10.000 und 100.000 Euro oder sogar darüber hinaus. Sie sind deshalb mit wesentlichen Extras und einer professionellen Qualität ausgestattet. Aufgrund der hohen Preisunterschiede bei diesen Geräten ist es unerlässlich, sich bereits im Voraus über die Möglichkeiten zu informieren und entsprechend die Auswahl zu begrenzen. Ein weiterer Aspekt, der bei einem Kauf zu bedenken ist, ist die Konstruktion des 3D-Druckers. Wie ist er aufgebaut? Ist es ein fertiges Modell oder ein Bausatz? Single-Extruder oder Mehrfach-Extruder? All diese Fragen und noch mehr gilt es zu beantworten. Nur wer die eigenen Wünsche kennt, kann sich den richtigen 3D-Drucker kaufen. Es existieren auf dem Markt offene Drucker, bei denen das Werkstück während des Druckvorgangs zugänglich ist. Bei geschlossenen Druckern kommen häufig Laser zum Einsatz. Diese Modelle sind zudem weniger oft auf dem Markt für Privatnutzer anzutreffen. Neben der Frage, ob der Drucker offen oder geschlossen arbeitet, stellt sich zusätzlich die Frage nach der Druckplatte. Einige 3D-Drucker verfügen über eine beheizte Arbeitsplatte. Bei einigen Druckmaterialien erweist sich eine solche beheizte Druckplatte als vorteilhaft, um ungleichmäßige Verformungen zu vermeiden. Gleichzeitig bedeutet das auch, dass bei jenen Herstellern ohne beheizbare Arbeitsplattform hauptsächlich PLA-Filamente nutzbar sind. Die Schichtauflösung spielt für den 3D-Druck ebenso eine Rolle wie die Genauigkeit beim Positionieren und die Geschwindigkeit beim Betrieb des Geräts. Was beeinflusst die Qualität beim 3D-Druck? Die Schichtdicke ist ein Argument, das besonders häufig angeführt wird, wenn es um die Druckqualität geht. Doch was heißt das für den Durchschnittsverbraucher konkret? Für den Kauf eines 3D-Druckers ist die Qualität ein wesentliches Kriterium. Worauf ist also bei den Angaben des Herstellers zu achten? Der dreidimensionale Druck funktioniert, weil mehrere Schichten aufeinander gedruckt werden. Das ist ungefähr genauso, als würde jemand Papier aufeinanderstapeln und dadurch eine bestimmte Form erzeugen. Nun ist es beim 3D-Drucker der Fall, dass sich die Schichten in ihrer Stärke (d. h. Dicke) unterscheiden. Fakt ist jedoch, dass die Fehlerwahrscheinlichkeit steigt, wenn ein Drucker mit geringeren Schichtstärken zum Einsatz kommt. Zudem unterscheiden sich die Schichtstärken hinsichtlich der genutzten Druckverfahren. Das Verfahren kann somit auf die Qualität Einfluss nehmen. Die folgende Auflistung zeigt typische Schichtstärken für unterschiedliche Druckverfahren: Oft vermuten die Anwender, dass eine geringere Schichtdicke automatisch mit einer verbesserten Qualität einhergeht. Das ist in vielen Fällen jedoch zu kurz gedacht. Kleine Modelle laufen Gefahr, während des Drucks zu überhitzen und sich dadurch zu verformen. Wer zudem plant, Objekte mit zu überbrückenden Hohlräumen zu drucken (»Bridging«, z. B. der Mittelstrich beim Buchstaben »H«), sollte sich bewusst sein, dass dünne Schichten leichter brechen, um die Hohlräume zu überbrücken. Insofern ist beim Kauf zu überlegen, welches Ziel mit dem 3D-Druck verfolgt wird. Für die Kaufentscheidung ist nicht nur auf die Schichtstärke zu achten. Die Druckdauer trägt ebenfalls zum Druckergebnis bei. Deshalb ist auch darauf zu achten, wie lange der Drucker benötigt, um das Projekt fertigzustellen. Zugleich ist zwischen der Druckdauer und der Druckgeschwindigkeit zu unterscheiden. Die Dauer zeigt an, wann das Objekt vollständig fertig gedruckt ist. Die Druckgeschwindigkeit hingegen gibt an, wie schnell sich die Düse bewegt, um die jeweilige Schicht aufzuspritzen. Beide Faktoren können für die Kaufentscheidung wichtige Kriterien darstellen. Die Dauer des Drucks ist für viele Käufer wesentlich. Kaum einer möchte lange auf das Druckergebnis warten. Deshalb neigen etliche Kunden dazu, einen 3D-Drucker zu kaufen, der schnell arbeitet. Kleine Objekte können bereits in wenigen Stunden fertig sein. Manche Modelle benötigen 24 Stunden oder mehr. Aber dabei vergessen viele, dass es für die Qualität maßgeblich ist, wie viel Zeit für den Drucker verfügbar ist. Hier gilt der Grundsatz: Je länger der Druck dauert, desto höher ist die Qualität der Verarbeitung. Was heißt das für die Druckgeschwindigkeit? Es kann vorkommen, dass preisgünstige 3D-Drucker zwar schnell arbeiten, aber unerwünschte Vibrationen auf der Druckplatte entstehen. Infolgedessen kann die Qualität des Objektes aufgrund der Schwingungen leiden. Teure 3D-Drucker zeichnen sich durch eine zügige Geschwindigkeit beim Druck bei gleichzeitig ruhigeren Bewegungsabläufen aus. Für den 3D-Druck sind viele verschiedene Materialien nutzbar und gängig. Dabei eignet sich nicht jedes Material automatisch für jeden 3D-Drucker. Bei einem Druckerkauf ist dies also unbedingt zu beachten. Auch hier stellt sich für Käufer wieder die Frage, was mit dem Drucker erstellt werden soll? Diese Überlegung trägt maßgeblich dazu bei, die Auswahl an Druckern einzuschränken, da nicht jeder Hersteller jedes Material empfiehlt. Neben PLA ist der Kunststoff ABS häufig für den privaten Gebrauch zu finden. Beide Sorten sind als Filament im Handel erhältlich. Das ABS basiert auf Erdöl und ist entsprechend komplexer in der Herstellung und Verwendung. Es ist weniger empfindlich, sobald es Umwelteinflüssen ausgesetzt ist. Allerdings ist bei der Verwendung im 3D-Drucker generell auf eine gute Lüftung zu achten, da das Material deutlich nach verbranntem Plastik riecht. Beim ABS liegt der größte Vorteil in der Hitzebeständigkeit begründet. ABS schmilzt nicht so leicht wie PLA. Außerdem ist es elastischer und weniger spröde. Wichtig: Der 3D-Drucker benötigt eine beheizbare Druckplatte. PLA und ABS stellen nicht die einzige Materiallösung für 3D-Drucker dar. Im Bereich der Polymere kommt ebenfalls TPU häufig zum Einsatz. TPU steht für »thermoplastisches Polyurethan«. Es handelt sich dabei um eine flexible Substanz, die beim 3D-Print Gummi simuliert. Das Material lässt sich unter dem Einfluss von Wärme wie Gummi ziehen. Anschließend nimmt es nicht wieder seine vorherige Form an. Daher ist es gut für den 3D-Druck geeignet – besonders in chemisch anspruchsvollen Umgebungen, da es resistent gegenüber Chemikalien ist. Weitere in der Industrie gerne genutzte Kunststoffe sind Polyamid, Polypropylen (PP), CPE, PTE-G, BioFila® (ein Biopolymer) und zahlreiche Gemische. Insbesondere der Bereich der Gemische ist vielseitig veränderbar. Häufig kommen Filamente für 3D-Drucker zum Einsatz, die zusätzliche Substanzen, wie z. B. Leuchtstoffe oder Metalle, enthalten. Sobald bei einem 3D-Drucker Laserstrahlen beteiligt sind, ist Harz das bevorzugte Material. Das Epoxidharz wird bereits lange in 3D-Druckern genutzt. Das flüssige Harz härtet unter dem Einfluss von UV-Licht aus. Zu diesem Zweck nutzen 3D-Printer Laser. Der größte Vorteil bei diesem Material ist die Tatsache, dass der Laser eine gezielte Anwendung ermöglicht. Für feine Figuren und Strukturen ist das Epoxidharz ein hervorragendes Material. Zusätzlich sind die herkömmlichen Schichten bei Figuren aus Harz zum Schluss kaum mehr erkennbar. Ein weiterer Werkstoff für den modernen 3D-Druck ist Metall. Speziell die industrielle Nutzung profitiert von dem Einsatz der Metalle. Die Raumfahrt, Luftfahrt und der Maschinenbau stellen nur drei der vielfältigen Einsatzmöglichkeiten von Metallen dar. Dabei unterscheiden sich die Metalle voneinander und nicht jedes eignet sich für den 3D-Druck. Häufig kommen Edelmetalle, Titan, Stahl oder Aluminiumlegierungen zur Verwendung. Anders als beim Kunststoff, der z. B. beim PLA auf einer Spule aufgewickelt ist, sind Metalle für 3D-Drucker als Pulver erhältlich. Auch in diesem Fall kommen Laser im Drucker zum Gebrauch, die das Metallpulver schmelzen, verkleben und ausbacken. Mittlerweile ist die Bandbreite an möglichen 3D-Druckmaterialien enorm. Nicht nur die klassischen Kunststoffe oder die hochwertigen Metalle und Harze sind gängige Materialien beim Druck. Daneben kommen für einige Hersteller von 3D-Druckern ebenfalls Substanzen wie Gips, Keramik, Silikon oder Kunstwachs infrage. Insbesondere die künstlichen Wachse eignen sich gut für 3D-Druckobjekte mit vielen Details. Gips nutzen häufig 3D-Druckshops, um Nachbildungen echter Personen herzustellen. Beim Kauf eines 3D-Druckers ist der Blick auf das Material daher ebenso wichtig wie der Blick auf die Schichtstärken, Druckplatte oder den Preis. Auch das Material ist unterschiedlich teuer in der Anschaffung. Wer eher ein kleines Budget für die Nutzung des Druckers zur Verfügung hat, aber viele Objekte ausprobieren will, sollte stärker auf das Material achten. Beim Kauf eines 3D-Druckers spielen Hersteller vor allem bei der Qualität und beim Preis eine Rolle. In den letzten Jahren ist der Markt für 3D-Drucker gewachsen. Dementsprechend wächst auch der Anteil an Produktionsfirmen. Obwohl nicht überall gleichermaßen die 3D-Printer erhältlich sind, gibt es mittlerweile dennoch einige Firmen, die bekannt und beliebt sind. Zu den beliebteren Herstellern zählt vor allem Anycubic. Das chinesische Unternehmen hat sich längst einen Namen auf dem Weltmarkt gemacht. Die Preise für 3D-Drucker von Anycubic sind eher niedrig angesetzt, sodass sich die Geräte auch für den Durchschnittsbürger lohnen. Andere Hersteller wie BIBO, Sculpto+ und Dremel sind ebenfalls sehr beliebt. Für den Heimgebrauch bieten sich außerdem die Hersteller Giantarm, Geeetech und Monoprice an. All diese Unternehmen bieten gute Lösungen für die heimische Freude am 3D-Druck an. Die Entwicklung des 3D-Drucks bietet viele spannende Möglichkeiten – sowohl industriell als auch experimentell und privat. Durch den Einsatz von 3D-Druckern sind beispielsweise Geometrien möglich, die anders nicht herstellbar wären. Das beste Beispiel stammt aus dem Bereich des Leichtbaus. Dabei lässt sich erheblich Materialgewicht sparen, indem z. B. Aluminiumlegierungen im 3D-Drucker erzeugt werden. Manch einer spricht bereits von einer »industriellen Revolution« durch das Aufkommen von 3D-Druckern. Allerdings sind die Drucker längst nicht geeignet, um sämtliche Produktionsbereiche der Industrie zu ersetzen. Zeit, Qualität und Kosten spielen dabei eine wesentliche Rolle. Zudem ist das Urheberrecht stärker in dem Vordergrund gerückt, seit 3D-Drucker im Gebrauch sind. Bereits 1981 erfand der US-amerikanische Ingenieur Charles W. Hull das Verfahren Stereolithografie. Dieses Verfahren ist damit das älteste additive Verfahren zur Fertigung. Allerdings dauerte es weitere zwei Jahre, ehe die Stereolithografie praktisch umgesetzt wurde. Weitere zwei Jahre später (1985) war das erste 3D-Programm zur Konstruktion (CAD) verfügbar. Das Patent dazu folgte auf dem Fuße im Jahr 1986. Charles W. Hull zeichnete sich bereits 1984 als verantwortlich für die Entwicklung des ersten 3D-Druckers. Während das Lasersintern-Prinzip im Jahr 1987 erschien, kam der erste 3D-Drucker erst 1988 auf den Markt. Damit nicht genug, entwickelte sich die Technik beständig weiter. Das Fused Layer Modeling war ab 1991 durch das Ehepaar Crump etabliert. Mit dem Wechsel des Jahrtausends wuchs der Markt (und der Bedarf) an 3D-Druckern für den Privatgebrauch. Ab dem Jahr 2000 gab es die Polyjet-Technologie (MJM bzw. Multi-Jet-Modeling). Der erste FLM-Drucker für Privatnutzer kam schließlich 2010 in den Handel. Charles W. Hull wurde 2014 mit dem »Europäischen Erfinderpreis« ausgezeichnet. Zugleich wurde er im gleichen Jahr in die »National Inventors Hall of Fame« aufgenommen. Seine Erfindung hat maßgeblich zur heutigen Entwicklung der 3D-Drucker beigetragen. Praktisch zeitgleich mit Charles W. Hull entwickelte Dr. Robert J. Klebe im Jahr 1988 den ersten »Biodruck«. Diese Entwicklung vom sogenannten »Cytoscribing Prozess« ist unabänderlich mit einer der größten Errungenschaften des 3D-Drucks verknüpft: der Druck von Zellstrukturen in der Medizin. Die 3D-Drucker erfahren eine Modifizierung, damit sie biologisches Material drucken können. Dadurch konnten bereits DNA-Moleküle sowie Zellstrukturen produziert werden. Diese Errungenschaft des 3D-Druckers ist vor allem für die Krebsforschung von großem Interesse. Außerdem stehen die Chancen recht gut, dass der 3D-Biodruck in der Zukunft für Organtransplantationen nutzbar sein wird – auch wenn das Drucken funktionsfähiger Organe bei Weitem kein Kinderspiel ist. Der 3D-Druck ist ebenfalls im Bereich der Raumfahrt revolutionär. Elon Musk hat mit dem privaten Raumfahrtunternehmen SpaceX bereits den 3D-Druck für den Einsatz im Weltall eingesetzt. In dem Unternehmen entstehen die Brennkammern der Triebwerke von Raketen im 3D-Drucker. Nicht nur in der Raumfahrt ist der 3D-Druck eine große Weiterentwicklung.3D Drucker – Das Wichtigste in Kürze

3D Drucker kaufen

3D Drucker Test & Vergleich

Die Top 5 Bestenliste aus unserem 3D Drucker Test

🥇 Platz 1: ANYCUBIC MEGA-S 3D-Drucker [Unser Testsieger]

Eigenschaften & Besonderheiten

Infos zum Hersteller Anycubic

![]()

🥈 Platz 2: Geeetech® 3D Drucker Acrylic Prusa I3 Pro B 3D-Drucker Kit

Eigenschaften & Besonderheiten

Technische Fakten zum Geeetech® 3D-Drucker Kit

Infos zum Hersteller Geeetech®

![]()

🥉 Platz 3: ANYCUBIC Chiron 3D-Drucker – automatische Kalibrierung in Echtzeit

Eigenschaften & Besonderheiten

Technische Fakten zum Anycubic Chiron 3D-Drucker

Infos zum Hersteller Anycubic

![]()

Platz 4: 3D-Drucker Ender 3 Pro, Creality Ender 3

Eigenschaften & Besonderheiten

Technische Fakten zum Ender 3 Pro 3D-Drucker

Infos zum Hersteller Creality 3D

![]()

Platz 5: BIBO 2 3D-Drucker – drucken, gravieren, schneiden und kopieren

Eigenschaften & Besonderheiten

Technische Fakten zum 3D-Drucker Bibo 2

Infos zum Hersteller Bibo

![]()

Wie funktioniert ein 3D-Drucker?

Damit verständlich ist, was die Vorzüge (und Schwächen) eines 3D-Druckers sind, lohnt es sich, die Funktionsweise vom 3D-Drucker zu betrachten. Wie funktionieren 3D-Drucker? Die Grundlage jedes dreidimensionalen Drucks ist das Modell bzw. die 3D-Vorlage. Darin sind alle Spezifikationen für den Druck festgehalten, sodass der Drucker präzise das Werkstück drucken kann.

Damit verständlich ist, was die Vorzüge (und Schwächen) eines 3D-Druckers sind, lohnt es sich, die Funktionsweise vom 3D-Drucker zu betrachten. Wie funktionieren 3D-Drucker? Die Grundlage jedes dreidimensionalen Drucks ist das Modell bzw. die 3D-Vorlage. Darin sind alle Spezifikationen für den Druck festgehalten, sodass der Drucker präzise das Werkstück drucken kann.Modelle, Vorlagen und Eigenkreationen – die Basis für 3D-Druck

Filamente: Diese Stoffe eignen sich besonders gut für den 3D-Druck

Extruder: It’s getting hot!

So druckt der 3D-Drucker!

FDM vs. SLA: 3D-Druckverfahren für Privatnutzer

Anwendung & Einsatzbereiche

Einzel- vs. Serienfertigung

Industrie vs. Privatnutzung

Wissenschaft vs. Kunst

Architekten und das Bauwesen

Welche Typen von 3D-Druckern gibt es?

Komplett montierte 3D-Drucker

3D-Drucker als Bausatz

Multiple 3D-Drucker

Vorteile eines 3D-Druckers

Der größte Vorteil von 3D-Druckern liegt in der schieren Masse an umsetzbaren Ideen begründet. Kaum eine Idee für ein Objekt lässt sich heutzutage nicht durch einen 3D-Drucker realisieren. Ob dekorativ oder tatsächlich praktisch nutzbringend – der 3D-Druck bringt die Produktion in vielfacher Hinsicht voran. Die Printer für dreidimensionale Gegenstände sind außerdem fähig, komplizierte Geometrien präzise zu drucken. Das macht die Geräte und die Technologie für die Wissenschaft und Forschung zunehmend unverzichtbar.

Der größte Vorteil von 3D-Druckern liegt in der schieren Masse an umsetzbaren Ideen begründet. Kaum eine Idee für ein Objekt lässt sich heutzutage nicht durch einen 3D-Drucker realisieren. Ob dekorativ oder tatsächlich praktisch nutzbringend – der 3D-Druck bringt die Produktion in vielfacher Hinsicht voran. Die Printer für dreidimensionale Gegenstände sind außerdem fähig, komplizierte Geometrien präzise zu drucken. Das macht die Geräte und die Technologie für die Wissenschaft und Forschung zunehmend unverzichtbar.

Gibt es Nachteile beim 3D-Drucker?

Für wen ist ein 3D-Drucker geeignet?

3D-Drucker für Otto-Normal-Verbraucher

Alternativen zu 3D-Druckern

Kaufkriterien: Was ist bei 3D-Druckern zu beachten?

Preis – Wie teuer ist ein 3D-Drucker?

Konstruktion des 3D-Druckers – Details für die Kaufentscheidung

Qualität – die richtige Schichtstärke beim 3D-Druck

Die Schichtstärken werden für gewöhnlich in Micron (µ) oder Millimeter (mm) angegeben. 10 Micron entspricht demnach 0,01 mm und 100 Micron sind 0,1 mm. Als Grundsatz gilt: Je dünner eine Schicht gedruckt wird, umso feiner ist die Darstellung und umso weniger sind die einzelnen Schichten beim fertigen Objekt erkennbar. Aber das genügt nicht als alleiniges Kriterium für den Kauf. Denn mit der dünneren Schicht geht ebenfalls ein höherer Preis einher. Auch die Druckdauer kann dadurch beeinflusst sein. Darauf geht ein späterer Abschnitt ein.

Dauer des Drucks als weiteres Qualitätsmerkmal von 3D-DruckernDruckmaterialien für 3D-Drucker

Beliebte Kunststoffe für 3D-Drucker: PLA, ABS und TPU

Am häufigsten sind Kunststoffe für 3D-Drucker im Handel anzutreffen. Dazu zählt das im Heimgebrauch beliebte PLA. Die Abkürzung steht für Polyactide. Der Kunststoff ist leicht zu nutzen. Sobald es keinerlei Zusätze enthält und farblos ist, zerfällt es zu den natürlichen Komponenten, wenn es den Einflüssen der Umwelt ausgesetzt wird. Das ist einerseits praktisch, andererseits ist es immer noch ein Kunststoff, der besser über die Wertstoffsammlung entsorgbar ist. Das PLA ist auf dem Markt in zahlreichen Varianten erhältlich. Spezielle Mischungen und etliche Farben sind erhältlich. Ein weiterer Pluspunkt des PLA: Wenn der Extruder das Material verflüssigt, riecht es kaum. Nicht zuletzt sind die Umwelteigenschaften häufig unbedenklich, da das Material grundsätzlich auf natürlicher Milchsäure basiert.

Am häufigsten sind Kunststoffe für 3D-Drucker im Handel anzutreffen. Dazu zählt das im Heimgebrauch beliebte PLA. Die Abkürzung steht für Polyactide. Der Kunststoff ist leicht zu nutzen. Sobald es keinerlei Zusätze enthält und farblos ist, zerfällt es zu den natürlichen Komponenten, wenn es den Einflüssen der Umwelt ausgesetzt wird. Das ist einerseits praktisch, andererseits ist es immer noch ein Kunststoff, der besser über die Wertstoffsammlung entsorgbar ist. Das PLA ist auf dem Markt in zahlreichen Varianten erhältlich. Spezielle Mischungen und etliche Farben sind erhältlich. Ein weiterer Pluspunkt des PLA: Wenn der Extruder das Material verflüssigt, riecht es kaum. Nicht zuletzt sind die Umwelteigenschaften häufig unbedenklich, da das Material grundsätzlich auf natürlicher Milchsäure basiert.Weitere Druckmaterialien: Epoxidharz, Metall, Gips, Keramik, Silikon u. v. m.

Hersteller von 3D-Druckern

Wissenswertes über 3D-Drucker

Obwohl der 3D-Drucker in den letzten paar Jahren rasant an Bekanntheit und Beliebtheit gewonnen hat, existiert die Technologie bereits deutlich länger. An dieser Stelle sei daher die Geschichte des 3D-Druckers näher beleuchtet.Geschichte des 3D-Druckers

Errungenschaften dank 3D-Drucker

Das Voranschreiten vom Biodruck revolutionierte die Medizin. Der 3D-Druck kam beispielsweise 2002 zum Einsatz, um eine Niere in geringer Größe anzufertigen. Seit 2010 existiert ein offizielles und kommerziell genutztes Labor für den Bioprint. Dieses Labor forscht inzwischen am Gewebe der Knochen. Zwischenzeitlich konnte es einzelne Strukturen des Lebergewebes hervorbringen und tranplantieren. Der Biodruck nutzt FDM-Drucker.

Das Voranschreiten vom Biodruck revolutionierte die Medizin. Der 3D-Druck kam beispielsweise 2002 zum Einsatz, um eine Niere in geringer Größe anzufertigen. Seit 2010 existiert ein offizielles und kommerziell genutztes Labor für den Bioprint. Dieses Labor forscht inzwischen am Gewebe der Knochen. Zwischenzeitlich konnte es einzelne Strukturen des Lebergewebes hervorbringen und tranplantieren. Der Biodruck nutzt FDM-Drucker.